Noise slips through thin walls faster than most people realize. Conversations, televisions, even footsteps echo where they shouldn’t, cutting into privacy and peace. The fix comes from choosing sound insulation for walls that helps limit this transfer and brings everyday comfort back into the space. For many homeowners, better sleep, improved productivity, and a calmer household are the real results of a properly soundproofed wall. In apartments, duplexes, and home offices, where multiple uses overlap, controlling noise is often the difference between frustration and livability.

How Sound Travels Through Walls

Noise doesn’t move through walls in just one way. Different types of sound exploit different weaknesses in a wall assembly, which is why effective soundproofing requires more than a single fix.

Airborne Noise

Airborne noise, such as voices, televisions, or music, passes easily through gaps, seams, or cavities with little resistance. Standard construction with thin drywall provides minimal resistance, so airborne sound often carries directly into adjacent spaces.

Impact Noise

Impact noise, like footsteps or furniture vibrations, travels through studs and drywall, using the framing itself as a sound bridge. This type of noise exploits the physical connection between surfaces, making it harder to block without structural changes.

Hollow Cavities and Amplification

Hollow cavities in typical 2×4 framing act like amplifiers, letting sound reverberate inside before pushing through drywall. By contrast, a filled cavity disrupts this pathway, reducing how far sound waves can travel. A single sheet of drywall offers little resistance, but double layers or a filled assembly can significantly reduce noise transmission.

Weak Points in the Assembly

The key to managing these sound pathways is understanding that walls act as both barriers and conduits. Any weak point, from an unsealed outlet box to an empty cavity, can become an open door for noise. That’s why a single product swap rarely solves the problem.

Key Principles of Wall Soundproofing

Effective wall soundproofing comes down to four principles. Each addresses a different weakness in a typical wall assembly, and together they form the basis of any high-performance system.

Mass: Adding Heavier Layers

Mass is the most straightforward approach: heavier wall surfaces resist vibration. Type X drywall adds more weight than standard panels, making it harder for sound to pass through.

Damping: Reducing Vibrations

Damping reduces the transfer of vibration between surfaces. A compound like Green Glue, spread between drywall layers, converts vibration into a small amount of heat energy and interrupts sound before it passes through. Spread in a thin layer, these compounds can significantly cut vibration when used correctly.

Decoupling: Breaking Vibration Paths

Decoupling physically separates layers so vibration in one surface does not pass directly into the next. This is often achieved with resilient channels or sound clips, a technique common in theaters and studios.

Absorption: Filling Cavities with Insulation

Absorption fills hollow cavities with insulation, breaking up sound energy before it can bounce and amplify. Among available options, sound insulation for walls is one of the most reliable ways to stop airborne noise inside wall cavities.

Combining Principles for Better Results

On their own, each principle offers an incremental improvement. Combined, they form a much more effective barrier. That is why a high-performance wall system usually layers multiple approaches, with absorption at the core.

Best Sound Insulation for Walls

Insulation is the most practical way to add absorption inside the cavity. While mass and decoupling often require major structural changes, insulation fits directly into the framing with minimal disruption. The right product limits sound transfer, improves livability, and can be installed during remodels or new builds.

Adding sound insulation is also one of the most cost-effective strategies. Compared to specialty drywall or structural modifications, filling a cavity with dense, absorptive material provides an immediate boost to wall performance at a lower price point. In most projects, sound insulation is the first step contractors and homeowners take because it tackles the biggest weak spot: the empty space inside the wall.

Quiet Denim: Ideal Soundproofing Insulation

Quiet Denim brings acoustic performance, safe handling, and installation ease together in one product. The design properties make it an effective option for both new builds and remodels.

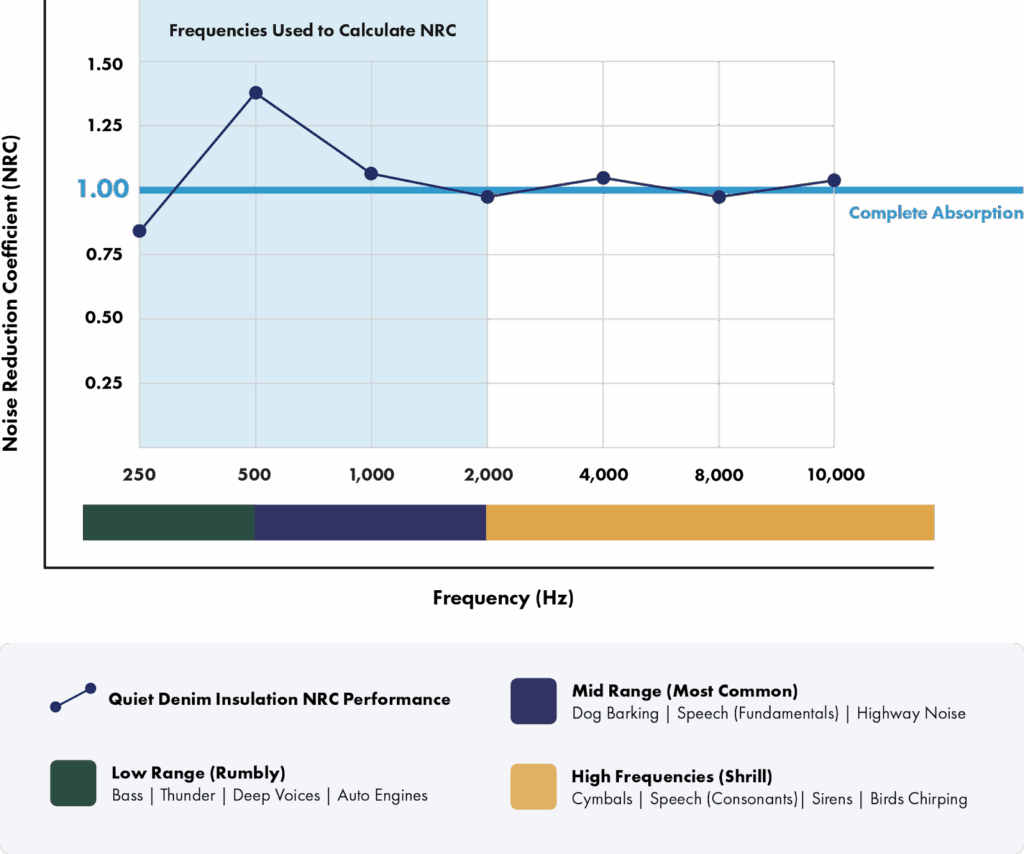

Acoustic Performance (NRC 1.05)

Quiet Denim is engineered from post-industrial recycled denim and designed with acoustics in mind. With a Noise Reduction Coefficient (NRC) of 1.05, it delivers very high sound absorption, far exceeding the performance of standard fiberglass batts, which often measure lower on NRC scales. Mineral wool can offer strong acoustic performance as well, but it may require protective equipment to avoid skin or airway irritation during install.

Quiet Denim NRC Performance 1.05:

Safe Handling and Indoor Air Quality

The Quiet Denim batts are low in VOCs, formaldehyde-free, and contribute to cleaner indoor air quality. Unlike itchy fiberglass, they are safe to handle and easy to install.

Simple Friction-Fit Installation

Quiet Denim uses a friction-fit design that presses into standard framing cavities without the need for extra fasteners, helping streamline installation.

Adaptable for New and Existing Walls

Quiet Denim adapts well to both new construction and remodels. In single-family homes, it can help create quieter bedrooms and more focused office spaces. In multifamily residences with shared walls, Quiet Denim can support better acoustic comfort between units.

How to Soundproof a Wall: Step-by-Step

Soundproofing a wall is not guesswork; it follows a clear sequence. Each step strengthens the assembly and reduces the weak points that allow noise to leak through.

- Open the Wall (If Not Already Exposed)

Renovations or drywall replacement provide the ideal opportunity to access the cavity. - Install Soundproof Insulation

Place Quiet Denim into the full cavity, pressing it in so the space is filled without gaps or voids. Ensuring consistent coverage helps the insulation absorb airborne sound before additional wall layers go up. - Add Damping Compound (Optional)

If additional layers of drywall are planned, apply a damping compound between sheets to minimize vibration transfer. Spread in a thin layer, these compounds can significantly cut vibration when used correctly. - Install Resilient Channels or Sound Clips (Optional)

For greater performance, decouple the drywall from the studs. These systems create a spring-like break that blocks vibration paths and are especially effective against impact-driven noise. - Finish with Additional Layers of Drywall

Thicker or multiple layers increase mass, further reducing noise. Type X or acoustic-rated panels are common options. - Seal All Gaps

Use acoustical sealant around outlets, seams, and perimeter joints. Even a small crack can act as a sound leak, undoing other improvements.

By layering these measures, homeowners can dramatically increase a wall’s ability to control both airborne and impact noise.

Soundproofing a Wall Between Rooms

Rooms on either side of a wall rarely share the same needs. Bedrooms require mid-range sound reduction for voices and televisions. Nurseries need protection from both low and high-frequency sounds. Home offices demand quiet to maintain focus, especially during remote work. This insulation suits all these cases, as it absorbs sound evenly across frequencies.

To maximize results, pair insulation with supportive measures. A solid-core door blocks more noise than a hollow-core alternative because of its added mass. Acoustic door seals close perimeter gaps that otherwise leak sound. Flooring choices also help, carpet or underlayment can cut flanking noise that bypasses wall assemblies. Used alongside insulation, these measures keep isolation consistent across the entire room.

Build a Better, Quieter Wall

Building a quieter wall improves livability by enhancing privacy and reducing daily stress. Good acoustic design isn’t a luxury, it is part of a home that actually works. Quieter spaces support sustained focus and overall well-being and can even improve resale value.

When evaluating sound insulation for walls, Quiet Denim stands out for its:

- Acoustic performance

- Friction-fit design

- Eco-conscious composition

Because it uses post-industrial recycled denim, it helps reduce textile waste that would otherwise end up in landfills. At the same time, its low-VOC composition supports healthier indoor air quality throughout the building’s lifespan. For contractors, it integrates into standard framing without added complexity. For homeowners, it provides a DIY-friendly approach to achieving professional-level noise control.

Learn More About Denim Insulation for Walls with Quiet Denim

Discover how denim insulation for walls can improve sound control, comfort, and indoor air quality. Quiet Denim offers NRC 1.05 performance, sustainable sourcing, and simple friction-fit installation, suitable for both remodels and new builds. Get a quote today and discover how it meets your project’s needs.